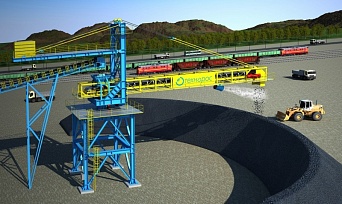

Stationary slewing stacker

The stacker is intended for taking coal from a conveyor for following forming radial coal storage of a mine. This equipment is designed for operations at ambient air temperature from -50 degrees C to + 40 degrees C and allows working with flammable and explosive materials in flammable and explosive environment.

The stacker steel structure is the base for all other units and consists of an immovable support, fixed on a rigid foundation, and an upper column, rotating about vertical axis.

On the support portal all elements of the stacker are settled. The upper contracture consists of a column, a swinging boom, a conveyor, a counterweight, a transfer bin and a boom lifting mechanism, which is a two-drum winch with blocks and tackles.

The material feeding is carried out through a transfer bin. The material discharging is carried out by free flow through an unloading unit. Taking into consideration the operations features, the stacker has drives with temperature sensor for preventing overheating and reducing thermal effect on handled material.

The control system, used in stackers, ensures:

- smooth automatic start-up

- electric motors and mechanism protection from overloads and personnel errors

- electric drive diagnostics

- automatic generation of informational messages about unacceptable working conditions of the stacker

- emergency stop of conveyors system and activation of the fire extinguishing systems and the emergency alert system - remote control

The stacker steel structure is the base for all other units and consists of an immovable support, fixed on a rigid foundation, and an upper column, rotating about vertical axis.

On the support portal all elements of the stacker are settled. The upper contracture consists of a column, a swinging boom, a conveyor, a counterweight, a transfer bin and a boom lifting mechanism, which is a two-drum winch with blocks and tackles.

The material feeding is carried out through a transfer bin. The material discharging is carried out by free flow through an unloading unit. Taking into consideration the operations features, the stacker has drives with temperature sensor for preventing overheating and reducing thermal effect on handled material.

The control system, used in stackers, ensures:

- smooth automatic start-up

- electric motors and mechanism protection from overloads and personnel errors

- electric drive diagnostics

- automatic generation of informational messages about unacceptable working conditions of the stacker

- emergency stop of conveyors system and activation of the fire extinguishing systems and the emergency alert system - remote control

Back to the list