Container crane RMG

Container cranes (container handlers) of the RMG type operate on a rail track and usually serve the railway front of the terminal. The RMG crane can perform the whole range of container handling: from unloading from the railway platforms and storage inside the crane gantry to loading them onto road transport.

To supply power to the electrical equipment, the crane is equipped with a flexible supply cable wound on a drum or a trolley system. The cranes are equipped with a slewing beam or slewing trolley for container turning.

In container handlers manufactured by TEHNOROS, high speed of container handling is ensured by U - shaped design with lower transom, which allows to carry 20, 40 and 45-foot containers between the crane supports without turning at the entire lifting height, as well as by the spatial suspension of the spreader, which dampens vibrations.

Additional options:

- Recovery system;

- Container addressable metering system;

- Integration into the TOS ("Smart Terminal") system;

- Cargo anti-sway system;

- Container anti-collision system;

- Remote crane monitoring system;

- Crane Operator Trainer.

Container crane (handler), RMG type

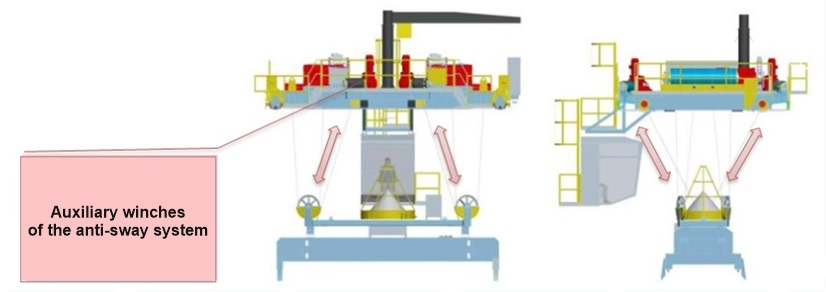

Effective spreader anti-sway system

Equipping cranes with 4 Active Anti-Sway System (AASS) winches allows to solve the following tasks:

1. Possibility to reload containers with displaced centre of gravity exceeding GOST 12.2.071-90. (GOST allows a deviation of 10% on both sides of the container, in our case 16% on the long and 25% on the narrow side of the container).

2. Spreader rotation when placing / removing the container by +/- 5 degrees.

3. Acceleration of the container reloading cycle, due to calming of the swinging spreader for 1.5 swinging cycles.

The cranes are equipped with a slewing beam or slewing trolley for turning containers. When a slewing trolley is used in the crane design, the spaced out support contour of the traverse reduces the sway of the container during movement, which increases the crane's productivity. It is also easier to handle containers with an offset centre of gravity.

Back to the list