Special bridge crane with a flexible or a rigid traverse suspension

Special bridge cranes are equipped with traverses to carry out different working procedures. These traverses are special load handling devices for handling of various cargo types.. They are usually removable and they are of beam space structure which is equipped with special gripping devices.

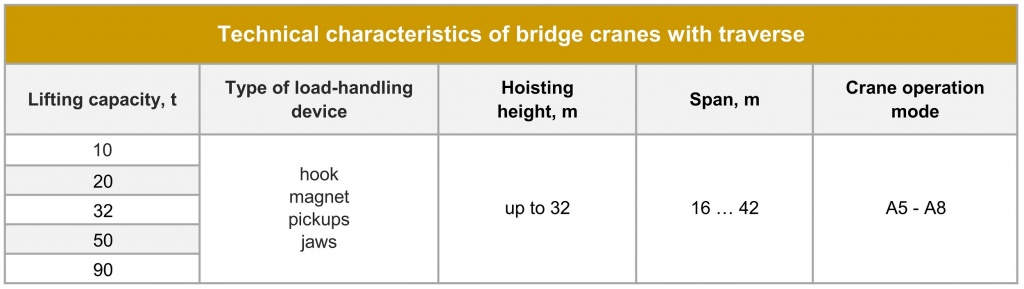

Depending on operational conditions and characteristics of the cargo to be handled traverses are divided into linear, dimensional, modular, mechanical and special types such as magnet, electromagnet, frictional and vacuum traverses with an appropriate type of gripping devices. Application of grippers of different types makes it possible to handle rolled steel, slabs, pipes, long cargoes and containers.

To diversify handling of various cargoes a bridge crane can be equipped with additional replaceable traverses of the required length. These traverses are provided with necessary gripping devices such as magnets, claws and operated claws for gripping. When gripping devices are removed and central or extreme traverse hooks are used the bridge crane can operate with piece cargoes in a hook mode.

A traverse is mounted to the bridge crane with its central part or with its end or longitudinal elements. In this case the traverse itself is located along or across the crane bridge. There are bridge crane structures with a flexible or a rigid traverse suspension. Cargo sway may occur if there is a flexible traverse suspension and this cargo sway can limit crane travelling speed. It is unacceptable for many processing procedures. In this case cargo anti-sway system is used to suppress possible oscillations.

If there is a rigid suspension the traverse is equipped with additional rods with guides. So, oscillations which occur while travelling along crane tracks are minimal ones and are determined by partial oscillations of the mine and the column with the cargo in relation to longitudinal axle of the bridge. Rigid traverse suspension due to higher travelling speed ensures larger cargo flow because time of positioning of the gripping device and time of cargo engagement is reduced. Bridge cranes with the rigid traverse suspension are frequently used in metallurgy in open-hearth steelmaking, mill and forging facilities.

Application of the traverse prevents the cargo from damage during its transportation and it also helps to position the cargo in points at different levels, to reduce hook lifting height as well as to handle long cargoes without impact of compressive & bending loads and to make cargo strapping procedure automatic.

While making configuration of crane units we take into consideration Customer’s production process particulars as well as individual requirements indicated in crane technical specification.

During production of special bridge crane with fixed and flexible traverse suspension we use components of leading manufactures and reliable suppliers.

Tehnoros company has got great experience in engineering, manufacturing and supplying of special bridge cranes with a flexible and a rigid traverse suspension for different branches of industry.

Back to the list