Special bridge crane with magnets

Special bridge cranes with magnets are intended to carry out handling procedures, transportation, installation and repair on outdoor platforms of different plants as well as in industrial workshops and warehouses.

Bridge cranes with magnets are equipped with a special cargo gripping device i.e. with an electric magnet which allows catching and handling of rolled steel, profiled bars, ingots, metal scrap, facings, scrap and other ferromagnetic materials. When electric magnet is removed cranes can operate with piece cargoes in a hook mode.

Configuration of special magnet cranes is similar to that of hook cranes for general purposes. Magnet cranes consist of a bridge with a travelling mechanism, one or two trolleys with lifting and travelling mechanisms, a cabin fastened to bridge metal structure and lifting electromagnets which are suspended on a hook or on a traverse while technological procedures are carried out.

The crane can be equipped with additional replaceable traverses mounted on hook suspensions to handle cargoes of different length. The traverses themselves can have different lengths. Quantity of magnets and their location on the traverse are variable. Depending on the length of the cargo to be handled a required quantity of electric magnets is suspended on the traverse in such a way so that the cargo will be located symmetrically in relation to the axis of the traverse.

Electromagnet power supply is carried out via a cable from a rectifier (220V–voltage, DC). Along with that the crane is equipped with an additional cable reel or a basket for electromagnet power supply at large hoisting height. The cable reel is switched off at work in a hook mode. Cargo magnets can be mounted on a hook suspension or on a traverse (with a flexible and a rigid suspension) located in longitudinal or cross direction in relation to the bridge.

Depending on their application cargo lifting electromagnets have different shape and configuration. They are divided into two basic types: round and rectangular ones.

Round electric magnets are of increased load lifting capacity and can be used for catching of old metal, metal scrap and slabs. These electric magnets have a molded sealed housing and they are made from high magnetic permeable steel.

Rectangular electromagnets are applied to transport long ferromagnetic materials, rectangular shaped materials and materials which have large magnet contact area for example rolled steel, section iron, slabs, blooms, rails and pressed forgings.

As a rule cargo lifting electromagnets are intended for transportation of cold cargo but can be manufactured as thermal resistant ones to allow handling of cargoes which temperature is up to 650°C. They can also be manufactured for operation under water. Besides that there are some types of electric magnets which enable to carry out specific technological operations, for example: unloading of metal scrap from wagons; cleaning of wagons from metal scrap; transportation of piles and coils from fittings, disks, rolled steel, handling of piled steel plates, lifting of large diameter rolls, reels and pipes.

Tehnoros company has got great experience in engineering, manufacturing and supplying of special cranes with magnets for different branches of industry.

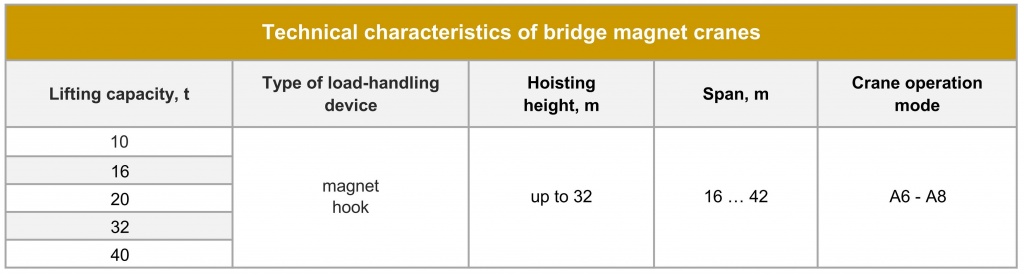

Below you can find technical parameters of the basic line of special bridge cranes with magnets. According to your wish, the technical parameters can be changed.

Back to the list