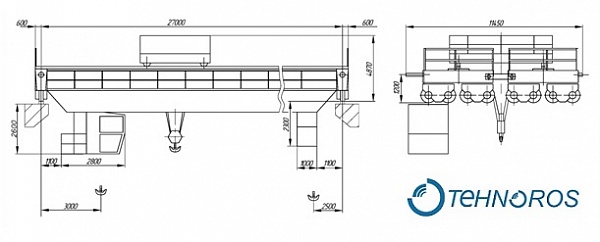

Metallurgical quenching bridge crane

The quenching metallurgical cranes are applied in heat-treatment shops of machinery works. They are intended for handling operations, which are necessary in quenching process. These operations include work pieces supply in heating furnaces, heated work pieces lifting, work pieces dipping into quenching tanks and a range of auxiliary operations of maintenance of heat-treatment shops equipment.

The metallurgical quenching crane consists of a bridge of standard framed construction (main longitudinal beams with end beams) and mechanisms, which have the increased speeds as compared with cranes for general purposes and, accordingly, higher installed power of electric motors. The high speeds load transfer are necessary for minimization of work piece heating temperature loss in order to provide a work piece structure homogeneity in volume. The high speeds are very important parameters of quenching cranes.

During crane units packaging, we take into consideration the specifics of the Customer’s manufacturing process, as well as individual requirements according to the technical specification.

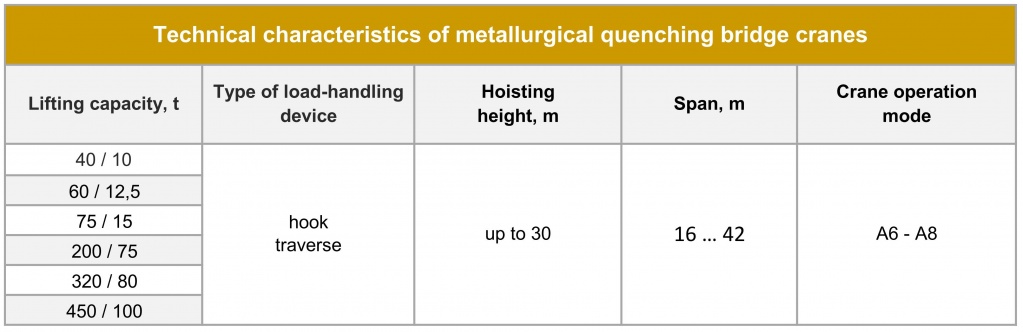

In the table you can find technical characteristics of the basic range of bridge metallurgical quenching cranes with lifting capacity from 40/10 tones to 450/150 tones. According to your wish, these parameters can be changed.

The metallurgical quenching crane consists of a bridge of standard framed construction (main longitudinal beams with end beams) and mechanisms, which have the increased speeds as compared with cranes for general purposes and, accordingly, higher installed power of electric motors. The high speeds load transfer are necessary for minimization of work piece heating temperature loss in order to provide a work piece structure homogeneity in volume. The high speeds are very important parameters of quenching cranes.

During crane units packaging, we take into consideration the specifics of the Customer’s manufacturing process, as well as individual requirements according to the technical specification.

In the table you can find technical characteristics of the basic range of bridge metallurgical quenching cranes with lifting capacity from 40/10 tones to 450/150 tones. According to your wish, these parameters can be changed.

Back to the list