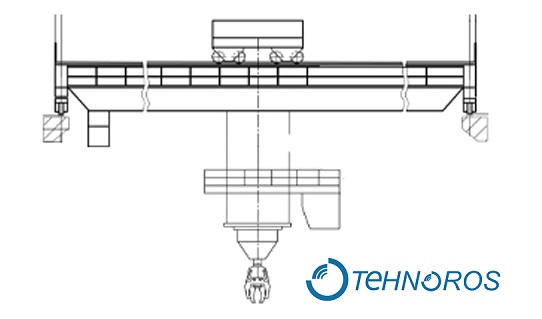

Metallurgical forge bridge crane

The forge crane consists of main and auxiliary trolleys, which moves on main and auxiliary bridges, connected by articulated hitches. The forge turner is fixed to the hook of the main trolley. The forge turner by means of the articulated chain holds a work piece during forging process and provides its rotation about horizontal axis. The forging process is made by the upper head of the press.

The forge cranes can travel a work piece by various methods: with a holder, without holder or in mount. As a rule, the holder is used during short work pieces treatment.

Because during forging the forge crane inevitably takes technological forces from the press or the hammer, during its designing we focus on reduction of dynamic overloads.

The forge crane lifting capacity is characterized by the sum of weights of a work piece and devices for work piece gripping.

The forge cranes can travel a work piece by various methods: with a holder, without holder or in mount. As a rule, the holder is used during short work pieces treatment.

Because during forging the forge crane inevitably takes technological forces from the press or the hammer, during its designing we focus on reduction of dynamic overloads.

The forge crane lifting capacity is characterized by the sum of weights of a work piece and devices for work piece gripping.

Back to the list