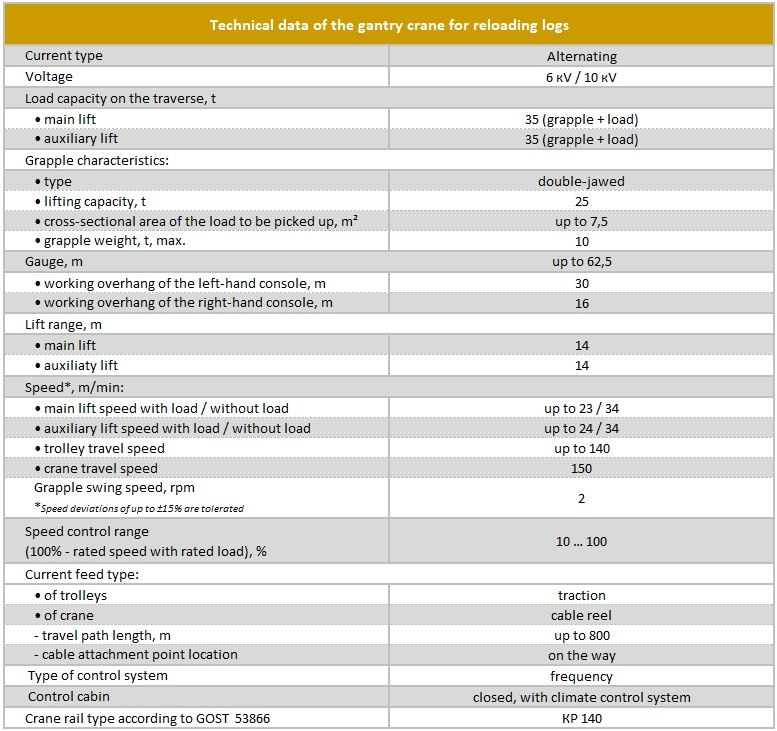

Log handling gantry cranes

Log handling gantry cranes are designed for the high-capacity handling of long materials in a timber yard.

The use of a rail-mounted gantry crane compared to wheel-mounted machinery significantly increases the line capacity, reduces handling costs and shortens the payback period of the investment.

Gantry crane running track takes up around 4% of a typical timber yard.

If the same warehouse is handled using wheeled transhipment equipment, the road and driveway area is 25%, a loss of 1,250 square metres for a typical 5,000 square metre warehouse. The Tehnoros gantry crane offers an additional 1,000 square metres of floor space, even without the option of stacking up to 13 metres in height, which increases the storage capacity considerably.

- 2 loading trolleys, which allows to pick up logs both from the lumber truck and from the trailer in one working cycle;

- The grapple jaws are wide - up to 1,650 mm, which ensures safe gripping of long log bundles without tipping. The safely gripped logs do not slip out of the bundle, do not form spills, do not hit themselves and do not create an emergency situation where a falling log can damage a vehicle, stationary storage equipment or cause injury to operating personnel.

- hydraulic swinging grapples with large capacity (up to 7.5 square metres in cross-section of the bundle to be handled, up to 2600 mm in width and up to 2750 mm in height). The large size of each grapple enables a full bundle of logs to be removed from the timber wagon at a time (one byte operation), which greatly reduces the unloading time for each truck and increases the turnover of the stockyard. The crane drives up to the lumber carrier, one trolley picks up the whole stack of logs from the machine, the second trolley picks them from the trailer, then, while the crane is moving with the material through the warehouse, the first lumber carrier, unloaded in one working movement, leaves the warehouse and the next one comes in its place;

- the grapple jaws are designed as transversal ribs, connected to one another, which reduces their weight significantly without losing functionality;

- The jaws of the grab fully follow the shape of the bundle of logs when closed, leaving no free space and preventing them from spontaneously shifting and falling out when moving around the warehouse;

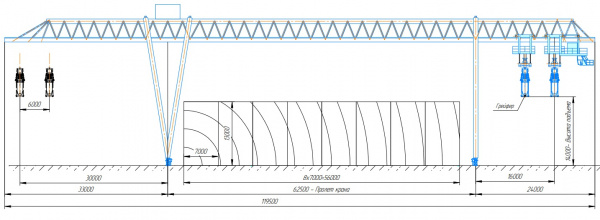

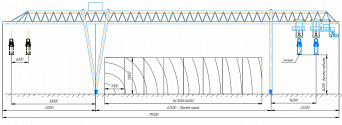

- the crane has a large span - up to 64 m, with 32 m and 24 m cantilevers. The total length of the bridge structure is up to 120 m. The width of the stack to be formed in the crane span is up to 56m (8 stacks 7m wide);

- Working mode - A8 according to GOST 34017;

- lifting capacity up to 70t (35t + 35t). The mass of reloaded logs in each grabber is up to 25t;

- High travel speeds: 150 m/min by crane and 140 m/min by trolley;

- A crane travel length of up to 800 m;

- Lift heights up to 20 m permitting stack heights up to 13 m;

- The crane control cabin is suspended from one of the trolleys, allowing the crane driver to always have a good view when performing complex transhipment operations;

- the crane is equipped with an automatic (semi-automatic) positioning system;

- a swing relief scheme that reduces the swing of the grapple and ensures optimal load torque distribution;

- an anti-skew system which allows the huge and heavy steel structure to travel at high speeds.

In addition to linear stockpiling, a radial arrangement is also possible, where the crane rotates around a fulcrum on a circular rail.

The use of a rail-mounted gantry crane compared to wheel-mounted machinery significantly increases the line capacity, reduces handling costs and shortens the payback period of the investment.

Gantry crane running track takes up around 4% of a typical timber yard.

If the same warehouse is handled using wheeled transhipment equipment, the road and driveway area is 25%, a loss of 1,250 square metres for a typical 5,000 square metre warehouse. The Tehnoros gantry crane offers an additional 1,000 square metres of floor space, even without the option of stacking up to 13 metres in height, which increases the storage capacity considerably.

The timber crane has the following features:

- 2 loading trolleys, which allows to pick up logs both from the lumber truck and from the trailer in one working cycle;

- The grapple jaws are wide - up to 1,650 mm, which ensures safe gripping of long log bundles without tipping. The safely gripped logs do not slip out of the bundle, do not form spills, do not hit themselves and do not create an emergency situation where a falling log can damage a vehicle, stationary storage equipment or cause injury to operating personnel.

- hydraulic swinging grapples with large capacity (up to 7.5 square metres in cross-section of the bundle to be handled, up to 2600 mm in width and up to 2750 mm in height). The large size of each grapple enables a full bundle of logs to be removed from the timber wagon at a time (one byte operation), which greatly reduces the unloading time for each truck and increases the turnover of the stockyard. The crane drives up to the lumber carrier, one trolley picks up the whole stack of logs from the machine, the second trolley picks them from the trailer, then, while the crane is moving with the material through the warehouse, the first lumber carrier, unloaded in one working movement, leaves the warehouse and the next one comes in its place;

- the grapple jaws are designed as transversal ribs, connected to one another, which reduces their weight significantly without losing functionality;

- The jaws of the grab fully follow the shape of the bundle of logs when closed, leaving no free space and preventing them from spontaneously shifting and falling out when moving around the warehouse;

- the crane has a large span - up to 64 m, with 32 m and 24 m cantilevers. The total length of the bridge structure is up to 120 m. The width of the stack to be formed in the crane span is up to 56m (8 stacks 7m wide);

- Working mode - A8 according to GOST 34017;

- lifting capacity up to 70t (35t + 35t). The mass of reloaded logs in each grabber is up to 25t;

- High travel speeds: 150 m/min by crane and 140 m/min by trolley;

- A crane travel length of up to 800 m;

- Lift heights up to 20 m permitting stack heights up to 13 m;

- The crane control cabin is suspended from one of the trolleys, allowing the crane driver to always have a good view when performing complex transhipment operations;

- the crane is equipped with an automatic (semi-automatic) positioning system;

- a swing relief scheme that reduces the swing of the grapple and ensures optimal load torque distribution;

- an anti-skew system which allows the huge and heavy steel structure to travel at high speeds.

In addition to linear stockpiling, a radial arrangement is also possible, where the crane rotates around a fulcrum on a circular rail.

Back to the list