Assembly Gantry crane

Assembly gantry cranes are used for installation of prefabricated industrial and civil buildings, for maintenance of erecting sites (of site joints) and equipment of petrochemical plants and enterprises of power industry including hydraulic electric stations and also during sectional installation and assembly work in shipyards and ship repair facilities.

Assembly gantry cranes are widely used during election of hydraulic technical structures, bridges and dams. Assembly cranes for hydraulic electric stations are of increased loading capacity. It ensures implementation of large-scale installation work under conditions of relatively small spans.

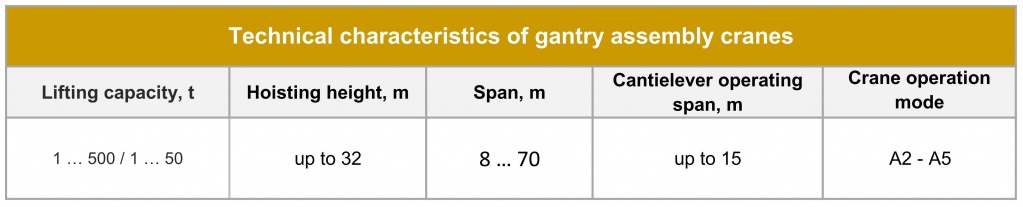

Technical specification of the main product range of gantry cranes with two trolleys is mentioned below. Upon your request values of parameters are changeable please fill in a magnet gantry crane questionnaire.

There are the following peculiarities of assembly cranes: increased height of a span structure as well as minimum possible weight (for cranes which are installed on building structures).

Assembly gantry cranes as a rule work on open platforms and are intended for implementation of handling procedures with piece cargoes. Structure of the assembly gantry crane consists of a single beam or a double beam bridge with one or two cantilevers or without cantilevers.

A drive of cargo lifting & trolley travelling mechanisms can be installed directly on a cargo trolley (self-propelled trolleys) or statically on a bridge (trolleys with a rope haulage).

Hooks manufactured according to GOST and hooks of special execution are used as a cargo gripping device of the assembly gantry crane. If necessary the cargo trolley is equipped with a hook traverse and with an electric hoist of auxiliary lifting.

Control of all crane mechanisms is carried out from control cabin and all crane mechanisms have individual drives. When there are large spans the cabin of the assembly crane can travel in a synchronized way with the cargo trolley or separately from it. It significantly improves visibility for an operator.

Control system by means of start-control electric equipment ensures speed control of crane procedures.

While making crane configuration we take into consideration Customer’s production process particulars and individual requirements indicated in crane technical specification.

While manufacturing assembly gantry cranes we use components of leading manufacturers and reliable suppliers.

Below you can find technical parameters of the basic line of gantry assembly cranes. According to your wish, the technical parameters can be changed.

Back to the list