Magnet gantry crane

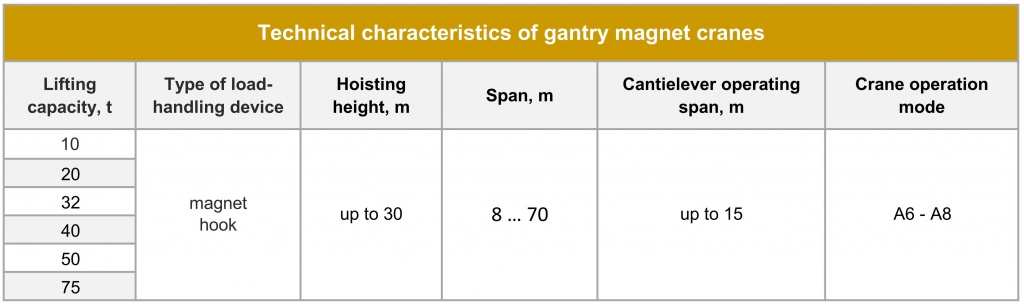

Magnet gantry cranes are intended for implementation of main procedures during handling and storage on open platforms of metallurgical plants, large scrap metal companies as well as scrap processing plants. By means of a permanent or an electric magnet which is suspended on a hook or on a traverse, the gantry crane can catch and handle plates and sections, blank parts, billets, metal scrap, chip scrap and other ferrous-magnet materials. Along with that magnet cranes can work with piece cargoes in a hook mode when the electric magnet is removed.

Depending on application, cargo hoisting electric magnets can have different configuration and geometrical shape (round or rectangular), The crane can be equipped with removable traverses (which are fastened on hook suspensions) for handling of cargoes of different length.

Cargo electric magnet can be installed on a hook suspension or on a traverse with a flexible suspension which is located in long and cross direction in relation to the bridge,

Traverses themselves can be of different length, a number and location of magnets on the traverse are changeable.

As a rule magnet gantry cranes are double cantilever cranes with a double girder bridge of metal sheet structure with a supporting double rail cargo trolley and a flexible (if necessary) control cabin.

Metal structure of the magnet gantry crane is a space structure from the bridge which is based on a rigid and a flexible support. This bridge consists of two span beams of box type which are connected with each other on ends with two end beams. This metal structure is intended for perception and transmission of all loads which occur during cargo hoisting and handling on a crane track.

Crane rails on which a cargo trolley (equipped with hoisting and travelling mechanisms) travels are laid on upper chords of span beams. To protect the trolley from atmospheric fallouts it is covered with special removable housings and a single housing. Required traverse is suspended to the cargo trolley by means of sheave blocks.

Spatial suspension allows to reduce time of a cycle and speed up handling procedures by means of reduction of swaying of a load handling device during starts, deceleration and by means of reduction of time for traverse centering adjustment.

While designing magnet gantry cranes much attention is paid to safety matters. In particular, a wiring scheme of the crane is made in such a way that while actuating appliance and security devices, magnetic strength is not removed from the magnet. Besides that, frequency control is applied on all crane mechanisms. It allows minimization of sudden speed rushes and motor torques, As a result, acceleration and braking action occur with pace which is set by software.

Control of electric magnets is carried out by means of a magnet station, which allows changing and controlling of real magnet current values and therefore, volumes of material to be handled.

While making crane configuration we take into consideration Customer’s production process particulars and individual requirements indicated in crane technical specification. While manufacturing magnet gantry cranes we use components of leading manufacturers and reliable suppliers.

Back to the list