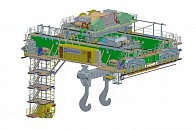

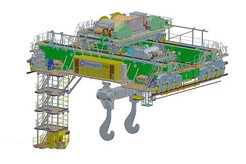

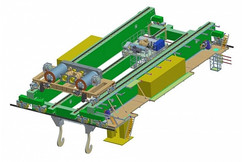

Metallurgical foundry bridge crane

The foundry bridge cranes are the main handling equipment, which is used at metallurgical enterprises for hot metal transportation, charging and casting. Generally, they are applied for charging molten cast iron into converters or into charging aisle of electric furnace, as well as for transporting a ladle with molten steel onto a receiving device or transporting molten steel onto a ladle furnace for further metal purification.

The foundry metallurgical cranes are divided into transporting, charging and casting cranes.

The transporting crane is intended for transferring a ladle with molten metal from a casting-ladle transfer car onto a turret of a continuous casting machine or a ladle furnace.

The charging crane maintains a firing house of a shop and charges ladles with molten cast iron into a converters or electric steel furnaces.

For converter steel casting in molds the casting crane is used.

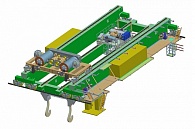

The foundry metallurgical cranes have, as a rule, several lifting mechanisms: the main one, intended for transferring a ladle with molten metal; the first auxiliary (and if necessary, the second one and the third one) lifting mechanism for ladle dumping during charging, and also other lifting mechanisms, intended to perform maintenance of equipment in the span.

During crane units packaging, we take into consideration the specifics of the Customer’s manufacturing process, as well as individual requirement according to the technical specification. During bridge metallurgical foundry crane manufacturing, we use components of leading manufactures and reliable suppliers.

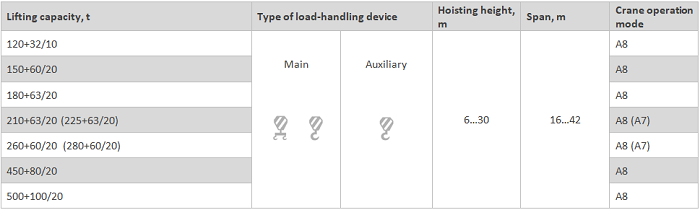

In the table you can find technical characteristics of the basic range of bridge metallurgical foundry cranes with lifting capacity from 80+20 tones to 500+100/20 tones. According to your wish, these parameters can be changed.

The foundry metallurgical cranes are divided into transporting, charging and casting cranes.

The transporting crane is intended for transferring a ladle with molten metal from a casting-ladle transfer car onto a turret of a continuous casting machine or a ladle furnace.

The charging crane maintains a firing house of a shop and charges ladles with molten cast iron into a converters or electric steel furnaces.

For converter steel casting in molds the casting crane is used.

The foundry metallurgical cranes have, as a rule, several lifting mechanisms: the main one, intended for transferring a ladle with molten metal; the first auxiliary (and if necessary, the second one and the third one) lifting mechanism for ladle dumping during charging, and also other lifting mechanisms, intended to perform maintenance of equipment in the span.

During crane units packaging, we take into consideration the specifics of the Customer’s manufacturing process, as well as individual requirement according to the technical specification. During bridge metallurgical foundry crane manufacturing, we use components of leading manufactures and reliable suppliers.

In the table you can find technical characteristics of the basic range of bridge metallurgical foundry cranes with lifting capacity from 80+20 tones to 500+100/20 tones. According to your wish, these parameters can be changed.

Back to the list